Is Fire Retardant Treated Wood Non Combustible: 3 Types [Covered]

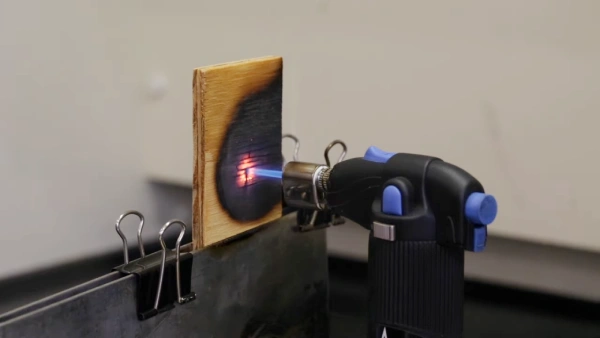

The use of fire retardant treated wood (FRTW) is becoming increasingly popular today for its fire safety benefits. Fire retardant-treated wood is specially processed wood subjected to chemicals and other treatments designed to reduce the rate and intensity of flame spread in the event of a fire.

FRTW can be used in place of non-combustible materials, providing a Class A, B, or C flame spread rating depending on the treatment and application.

But is fire retardant treated wood non-combustible? Though it is not considered non-combustible, FRTW can provide an additional layer of protection in the event of a fire.

Throughout this post, the focus will be on what chemicals are used in FRTW, if it is considered non-combustible, how it affects the strength & durability of wood and signs for identifying FRTW.

Is Fire Retardant Treated Wood the Same as Fire-Resistant Wood?

Fire retardant-treated wood and fire-resistant wood have some similarities but also distinct differences.

A fire-retardant-treated wood is a regular wood that has been chemically treated to reduce its flammability. In contrast, fire-resistant wood is specifically designed to resist ignition and prevent the spread of flames without additional chemical treatments.

Both types of wood provide some level of protection against possible fires but are not interchangeable.

The primary difference between the two is that fire-retardant-treated wood will still burn more slowly than untreated wood, while fire-resistant materials do not combust easily.

Fire retardant-treated wood is often referred to as FRTW and can be used in applications such as building construction or in furniture making where flame resistance is required but only for a limited time.

Typically, fire-resistant woods are labeled with the designation “FR.” They must pass specific tests to be certified for use in permanent structures such as homes or office buildings.

Another important factor when considering fire retardant and fire-resistant woods is their cost. Typically, fire retardant treated wood will cost more than untreated ones due to the additional chemical treatment they must undergo.

But depending on the application, they may still be more economical than using fire-resistant woods. For example, if the structure or furniture being built will only be used temporarily, it may make more sense economically to use FRTW instead of FR materials.

Is Fire Retardant Plywood Non Combustible?

Fire retardant plywood is a type of wood product that has been treated with fire retardants to make it more resistant to fire, smoke, and heat. While it is not completely non-combustible, its fire-retardant properties can provide extra protection in building construction.

Plywood that is fire retardant meets the requirements for Class A/Class 1 fire retardant materials as set by ASTM E-84, meaning it can resist fire spread and smoke production. This makes it an ideal choice for many applications where non-combustible materials are unavailable or cost prohibitive.

Aside from being UL Listed for general construction use, this plywood also has several other benefits. It is typically less expensive than other non-combustible materials such as concrete, steel, or aluminum. It can be used in place of them in some applications where weight and cost are issues.

Besides that, since the process used to treat plywood doesn’t change its look or feel significant, the material’s aesthetic properties remain unchanged compared to untreated wood products.

Fire retardant plywood also offers higher performance than regular wood products in terms of flame spread and smoke production resistance during testing scenarios. And while it may be slightly heavier than other wood products, this added weight helps increase its ability to resist fire and heat even further.

What Chemicals Are Used In Fire Retardant Wood?

Fire retardant wood is an important material used in construction and industry to ensure that buildings are safe and protected from fire hazards. It contains chemicals that slow down or stop fire spread through burning, charring and thermal insulation.

A fire retardant wood coating typically relies on an array of chemical compounds to slow down and prevent the spread of flame. The most commonly used chemicals in fire retardant wood are:

Halogens are among the most common elements in fire retardant wood coatings, with chlorine and bromine being halogen compounds utilized. These halogens react with combustible material by forming a char-like layer that creates a protective barrier that prevents the spread of flame, heat, and smoke.

Phosphorus is another compound used in fire retardant wood coatings, and it works in two ways. Firstly, phosphorus reacts with certain combustible materials to produce a flame-inhibiting char layer similar to what halogen chemicals do.

Secondly, phosphorus can also act as a catalyst for cross linking polymers found in some types of fire retardants, thus providing an extra layer of protection from heat and flame.

Nitrogen is also used in many fire retardants as it helps reduce the rate at which fuel burns when exposed to oxygen, thus limiting its ability to propagate flames.

And nitrogen can create an oxygen-depleted zone where combustible material may not be able to burn, thereby further reducing the risk that flames will spread.

Boric Acid and Borax compounds are also commonly used in fire retardants as they can form a stable char layer when heated that is effective at blocking out oxygen and preventing further burning or combustion of fuel sources.

Aside from that, these compounds are non-toxic compared to other chemical agents and have superior thermal stability. It makes them ideal for use in products designed for long-term protection from heat and flames.

Inorganic Metal Compounds such as copper oxide are also utilized in specific fire retardant formulations due to their high thermal conductivity. It helps transfer heat away from combustible materials, slowing down ignition rates or even preventing ignition altogether.

And these compounds feature high melting points that make them more resistant to burning than other chemicals involved in fire retardants where temperatures exceed their melting points.

Every type of chemical in fire retardant coatings serves its own unique purpose while working together to extend maximum fire protection. In normal conditions and use cases, combining ingredients like those above can mitigate fire damage without causing additional harm or injury.

Does Fire Retardant Treatment Affect the Strength and Durability of Wood?

While FR treatments can be extremely effective in protecting a structure, they can also negatively impact the strength and durability of the material.

When fire retardant chemicals are applied to a wood surface, they can often lead to increased levels of moisture being trapped within the material. This can weaken its overall structural integrity.

This is especially true with painted or sealed surfaces where trapped moisture can cause severe problems such as warping or splitting over time. Ans, FR treatments may also reduce strength in certain softwoods due to increased weight from added chemicals.

Regarding durability, FR treatments may also increase corrosion rates for metal connectors used in wooden structures since they may create an acidic environment around them that can speed up corrosion rates.

Similarly, certain plastic components may become brittle and break easier due to exposure to fire-retardant chemicals.

Accordingly, FR treatments offer significant advantages regarding fire protection but should be used judiciously as they could cause strength and durability issues with certain materials.

How Can You Tell If Wood Is Fire Treated?

Determining if a wood product is fire-treated or not requires careful scrutiny. The stamped label on the exterior or interior of the wood indicates that the product has been through a fire-retardant treatment process and carries the telltale “fire-rated treated” stamp.

This is why it is important to ensure any building materials being purchased have gone through this specific procedure, as without it, there can be no guarantees against future damage from high heat.

Buyers should take extra time to investigate their fire-treated wood sources and ensure that any supplier used is reputable and registered with associations such as NFPA’s National Fire Protection Association.

By diligently checking labels and taking responsibility, you can help ensure your projects are safe and secure in all conditions.

Fire Retardant Treated Wood: An Additional Layer of Fire Protection

Fire retardant treated wood provides an extra layer of fire protection compared to untreated wood. Despite not being non-combustible, this material offers a flame spread rating of Class A, B, or C, depending on its treatment and application.

The chemicals used for fire retardant treatment can vary depending on their intended purpose. But generally include halogens or inorganic metal compounds and more chemicals to provide added protection against flames without compromising the strength or durability of the wood.

Identifying FRTW may require specialized test methods, but usually, visible signs such as staining or discoloration along with labeling indicate it. So it’s essential to check for these signs before purchasing FRTW, or any building material for that matter.