Does a Propane Heater Need to Be Vented: Stay Safe

Yes, you need to vent a propane heater properly to avoid dangerous carbon monoxide buildup, which can be odorless and deadly.

Vented heaters channel exhaust outside, while ventless models release combustion gases indoors but require strict ventilation to maintain safe oxygen levels.

Improper or blocked venting risks poisoning, fire, and poor air quality. You must size and maintain vents according to the heater’s BTU output and follow all safety guidelines.

Understanding proper venting guarantees safe operation and peace of mind.

Key Takeaways

- Vented propane heaters require exhaust vents to safely expel combustion gases outdoors and prevent indoor carbon monoxide buildup.

- Ventless propane heaters release combustion byproducts directly indoors and must have strict fresh air ventilation to ensure safety.

- Using propane heaters in airtight or poorly ventilated spaces without proper venting increases carbon monoxide poisoning risk.

- Proper vent sizing and placement, following manufacturer guidelines, are essential to maintain safe oxygen levels and prevent toxic gas buildup.

- Installing carbon monoxide detectors and ensuring unobstructed venting are critical safety measures when using propane heaters.

Why Proper Ventilation Matters for Your Propane Heater?

Because propane heaters produce combustion byproducts like carbon monoxide, proper ventilation is essential to keep your indoor environment safe.

You must make certain all combustion gases exit your living space efficiently to prevent toxic buildup. Whether your heater is vented or ventless, adequate airflow is non-negotiable.

Vented units use flues or ducts to channel exhaust outdoors, while ventless models rely on sufficient room ventilation. Without this, carbon monoxide, an odorless, colorless poison, can accumulate rapidly, causing severe health risks.

You also need ventilation to avoid propane leaks, which increase fire and explosion hazards. Follow manufacturer guidelines precisely, including minimum vent area calculations and required openings.

Always maintain clear, unobstructed vents to guarantee proper exhaust flow. Neglecting ventilation compromises safety and performance, so never operate a propane heater in sealed spaces.

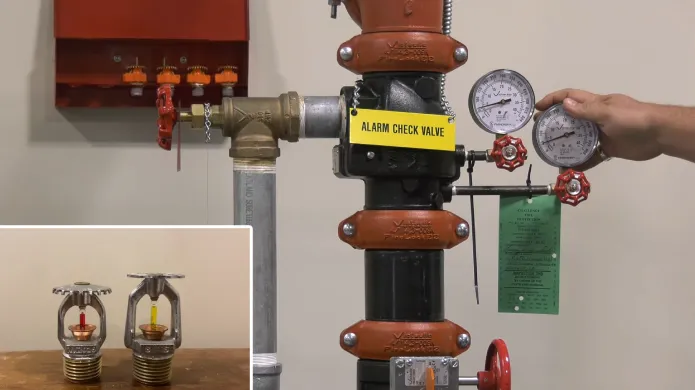

Proper ventilation also helps prevent conditions that could inadvertently trigger fire sprinkler activation in connected safety systems.

How Propane Combustion Produces Dangerous Gases?

When propane combusts, it reacts with oxygen to produce heat, water vapor, and carbon dioxide, which is what we want under ideal conditions.

But here’s the catch: if the combustion isn’t complete, it can create some harmful byproducts. One of the most concerning ones is carbon monoxide. It’s a colorless and odorless gas, and that’s what makes it really dangerous since it can lead to severe poisoning risks without any warning signs.

Proper ventilation and regular maintenance are essential to prevent the buildup of dangerous gases in enclosed spaces.

Propane Combustion Process

Understanding propane combustion is essential for recognizing how dangerous gases form during heater operation. When you ignite propane (C3H8), it reacts with oxygen (O2) from the air, producing carbon dioxide (CO2) and water vapor (H2O) in a complete combustion reaction.

However, if oxygen supply is insufficient, incomplete combustion occurs, generating carbon monoxide (CO), a colorless, odorless, and highly toxic gas. Additionally, trace amounts of nitrogen oxides (NOx) may form due to high combustion temperatures.

These byproducts accumulate rapidly without proper ventilation, posing serious health risks. You must make certain that your propane heater receives adequate oxygen and exhausts combustion gases safely.

Proper combustion control and ventilation prevent dangerous gas buildup, safeguarding indoor air quality and occupant safety. Always follow manufacturer guidelines and maintain ventilation systems to support complete combustion.

Installing fire sprinklers in residential areas can further enhance safety by detecting heat and suppressing fires that may result from heater malfunctions.

Harmful Byproducts Generated

Although propane combustion ideally produces only carbon dioxide and water vapor, incomplete combustion can generate harmful gases that threaten your safety.

When the fuel-to-air ratio is incorrect or ventilation is insufficient, propane doesn’t fully oxidize, producing toxic byproducts like nitrogen oxides (NOx), formaldehyde, and trace amounts of unburned hydrocarbons.

These gases can irritate your respiratory system and degrade indoor air quality. Additionally, combustion produces particulate matter that can exacerbate health issues. To minimize exposure, you must ensure proper ventilation and regular heater maintenance.

Monitoring combustion efficiency through professional inspections helps detect and correct incomplete burning. Never ignore signs like yellow flames or soot deposits, as they indicate unsafe combustion conditions generating these hazardous byproducts. Proper venting and adherence to safety guidelines are essential to protect you and others from these dangers.

Just as fire-treated wood requires proper sealing to maintain its protective qualities and prevent deterioration, propane heaters need adequate ventilation to ensure safe and complete combustion.

Carbon Monoxide Risks

Carbon monoxide poses a serious risk whenever propane burns without adequate oxygen. When combustion is incomplete, your propane heater produces carbon monoxide (CO), a colorless, odorless gas that can quickly accumulate indoors.

This happens because propane reacts with oxygen to generate heat, water vapor, and carbon dioxide under ideal conditions. However, if oxygen supply is insufficient, CO forms instead, posing lethal hazards.

To prevent this, you must ensure proper ventilation through direct venting systems or adequate room airflow. Always install your heater following manufacturer guidelines and local codes, providing necessary vent openings sized per BTU output.

Neglecting ventilation can lead to CO buildup, causing headaches, dizziness, or worse, fatal poisoning. Use CO detectors and maintain your heater to protect your indoor air quality and safety.

Proper ventilation also helps maintain air circulation while containing potentially hazardous gases, similar to recommended practices in spill containment.

Vented vs. Ventless Propane Heaters: What You Need to Know?

When choosing between vented and ventless propane heaters, you need to weigh safety and ventilation requirements carefully.

Vented heaters use ducts or flues to expel combustion gases outdoors, minimizing indoor carbon monoxide risks. Ventless heaters release combustion byproducts directly into the room, requiring strict ventilation protocols to avoid hazardous gas buildup.

Consider these key points:

- Vented heaters demand professional installation with precise vent sizing and routing to guarantee exhaust removal.

- Ventless heaters must operate in well-ventilated spaces, maintaining minimum fresh air openings to dilute combustion gases safely.

- Improper ventilation or blocked vents in either system can cause dangerous carbon monoxide accumulation and fire hazards.

Always follow manufacturer guidelines and local codes to maintain safe indoor air quality when using any propane heater.

How to Calculate Proper Vent Size for Your Propane Heater?

Understanding the differences between vented and ventless propane heaters sets the stage for accurately sizing your venting system. To ensure safe combustion gas removal, calculate vent size based on your heater’s BTU rating.

Most models require 3-4 square inches of vent area per 1,000 BTUs. You must provide two vents, one low and one high, to promote airflow.

| Heater BTU Output | Vent Area per 1,000 BTU (sq. in.) |

|---|---|

| 10,000 | 4 |

| 30,000 | 4 |

| 125,000 | 3 |

| NFES 006187 Tent | 594 (4.125 sq. ft.) |

Calculate total vent size, then divide equally between intake and exhaust openings to maintain safe, effective ventilation.

Common Venting Methods for Propane Heaters

To set up your propane heater safely, you’ll need to choose an appropriate venting method that guarantees efficient removal of combustion gases.

Choosing the right venting method is essential for safely removing combustion gases from your propane heater.

Proper venting prevents carbon monoxide buildup and assures safe operation. Here are three common venting methods:

- Direct Vent Systems: These draw combustion air from outside and expel exhaust outdoors through sealed pipes. This eliminates indoor air contamination risks.

- Horizontal Venting: Running vents through exterior walls, this method suits buildings without attics. It requires precise sealing and correct pipe angles to avoid blockages.

- Vertical Venting: Extending vents through roofs, vertical systems need flashing and caps to prevent water intrusion and assure unobstructed exhaust flow.

Selecting the right vent type depends on your heater model, installation location, and local codes. Always follow manufacturer guidelines and consult professionals to maintain safety and compliance.

Regular inspection for corrosion and maintenance of the venting system help ensure long-term safe operation.

Risks of Using Propane Heaters Without Adequate Ventilation

Although propane heaters provide efficient warmth, using them without adequate ventilation can lead to dangerous indoor air quality issues.

You risk rapid carbon monoxide buildup, an odorless, colorless gas that can cause poisoning or death. Inadequate airflow also allows propane leaks to accumulate, increasing fire and explosion hazards.

Even opening windows often won’t provide sufficient ventilation, especially in cold conditions where doors and windows remain mostly closed. Blocked vents or improper installation can further trap combustion byproducts indoors, reducing heater performance and safety.

To protect yourself and others, make sure your propane heater operates with correctly sized vents or fresh air openings. Neglecting ventilation compromises air quality, posing severe health and fire risks you can avoid by adhering to strict ventilation requirements.

For enhanced safety, consider installing a fire suppression system to help control potential fire hazards associated with propane leaks and combustion byproducts.

Installation Tips for Safe Propane Heater Venting

When installing your propane heater, it’s super important to position those vents just right. You want to ensure proper airflow and steer clear of any backdrafts that could cause issues.

Don’t forget to seal all the connections using high-temperature silicone. This little step can make a big difference in maintaining efficiency and safety.

Plus, insulating any exposed sections is a smart move to keep everything running smoothly.

And hey, if you’re ever in doubt, it’s always a good idea to consult with a certified HVAC professional. They can help make sure your installation ticks all the boxes for safety codes and follows the manufacturer’s specifications. Better safe than sorry, right?

Proper Vent Placement

When installing a propane heater, placing vents correctly guarantees safe and efficient removal of combustion gases. You must make certain vents allow proper airflow to prevent carbon monoxide buildup and maintain heater performance.

Focus on these key points:

- Position two vents per heater specifications: one low and one high, each sized to provide adequate square inches per 1,000 BTU output.

- Install vents on exterior walls or roofs per manufacturer instructions, using appropriate materials like stainless steel pipes and termination caps.

- Maintain clear vent paths free from obstructions such as debris or snow, and angle pipes correctly to promote exhaust expulsion and prevent backflow.

Proper venting is crucial to avoid foul odors and hazardous gases from accumulating inside the building.

Sealing and Insulation

Proper vent placement guarantees effective airflow, but sealing and insulating the vent system safeguards against leaks and energy loss. You must use high-temperature silicone sealant at all pipe joints to prevent gas or exhaust leaks.

Wrap insulation around vent pipes to maintain heat and avoid condensation, which can cause corrosion or blockages.

| Task | Recommended Material |

|---|---|

| Pipe joint sealing | High-temperature silicone |

| Pipe insulation | Fiberglass or foam wrap |

| Exterior wall sealing | Weatherproof caulk |

| Roof flashing | Metal flashing with sealant |

| Vent termination | Cap with insect screen |

Sealing prevents carbon monoxide intrusion and improves efficiency. Proper insulation reduces thermal loss, ensuring safe and efficient vent operation. Inspecting and sealing any cracks or gaps regularly with high-quality caulk or sealant is essential to maintain the integrity of the vent system.

Professional Installation Advice

Although vent installation might seem straightforward, assuring a propane heater’s venting system meets safety and efficiency standards requires professional expertise.

You must prioritize proper vent sizing, secure sealing, and correct placement to prevent carbon monoxide hazards and maintain peak performance.

Here are key installation tips:

- Calculate vent area precisely. Use at least 4 square inches per 1,000 BTUs and provide two vents (one low, one high) for balanced airflow.

- Use certified components like stainless steel pipes, elbows, and high-temperature sealants to withstand heat and prevent leaks.

- Position the heater on an exterior wall, align vent tubing accurately, and follow manufacturer instructions for mounting and sealing to assure compliance with safety codes.

Always hire a certified professional for installation to guarantee your safety.

Additionally, selecting materials that meet fire retardant standards can enhance the overall safety of the venting system.

Maintaining and Inspecting Propane Heater Vents for Safety

Since propane heater vents handle combustion byproducts, you must inspect them regularly to guarantee unobstructed airflow and prevent dangerous gas buildup.

Check vents for blockages like debris, snow, or nests that could restrict exhaust flow.

Examine vent pipes and connections for damage, corrosion, or loose fittings that might cause leaks.

Make sure vent terminations remain clear and properly sealed to avoid backdrafts.

Clean vents annually, or more often in harsh environments, using manufacturer-recommended methods.

Verify that vent angles and slopes promote efficient exhaust expulsion according to installation guidelines.

Regular inspection helps you detect issues early, maintaining safe operation and preventing carbon monoxide accumulation.

If you spot damage or improper venting, address it immediately or consult a certified HVAC professional.

Consistent maintenance safeguards your space from toxic gas hazards and system malfunctions.

When Portable Propane Heaters Need Extra Ventilation?

When you use portable propane heaters indoors or in confined spaces, you must provide extra ventilation beyond standard requirements to prevent dangerous carbon monoxide buildup and maintain safe air quality.

Portable units rely heavily on adequate airflow to dilute combustion gases. You should:

- Make certain ventilation openings total at least 4 square inches per 1,000 BTU output, positioned low and high to promote air exchange.

- Avoid using these heaters in airtight rooms or tents without dedicated fresh air inlets, as stagnant air increases toxicity risks.

- Regularly inspect vents for obstructions such as snow or debris that can restrict exhaust flow and cause hazardous gas accumulation.

Following these guidelines helps maintain safe oxygen levels and prevents toxic gas buildup when using portable propane heaters in enclosed environments.

What to Do If You Suspect Gas Leaks or Poor Ventilation?

If you notice the smell of gas or suspect poor ventilation around your propane heater, shut off the fuel supply immediately and evacuate the area.

Do not operate any electrical switches or devices that might generate sparks.

Once outside, call your gas provider or emergency services to report the suspected leak.

Avoid reentering the space until professionals confirm it’s safe.

To prevent poor ventilation, make sure vents are unobstructed and sized according to your heater’s BTU output, following manufacturer and safety standards.

Regularly inspect venting components for damage or blockages.

Install carbon monoxide detectors nearby to monitor air quality continuously.

If you detect symptoms like dizziness or headaches indoors, leave immediately and seek fresh air.

Prompt action minimizes risks of carbon monoxide poisoning, explosions, or fires linked to propane heater use.

Frequently Asked Questions

Can I Use a Propane Heater in a Small, Sealed Room Safely?

You shouldn’t use a propane heater in a small, sealed room safely because combustion gases, including deadly carbon monoxide, will build up quickly.

Without proper ventilation, like vent openings or direct venting, you risk poisoning or fire.

Always make certain at least 4 square inches of vent area per 1,000 BTUs or follow your heater’s specific requirements.

For safety, keep the space well-ventilated or use outdoor-rated heaters only.

How Often Should Propane Heater Vents Be Professionally Inspected?

You should have your propane heater vents professionally inspected at least once a year to guarantee safe operation.

Annual inspections help detect blockages, corrosion, or leaks that could lead to dangerous carbon monoxide buildup or inefficient combustion.

If you use your heater frequently or in harsh conditions, consider more frequent checks.

Always hire certified HVAC professionals to verify vent integrity, secure connections, and compliance with safety standards to protect you and your property.

Are There Specific Venting Requirements for Propane Heaters in RVS?

Back in the age of knights, you’d want your castle well-ventilated; similarly, in your RV, you must follow specific venting rules for propane heaters.

You need properly sized vents, usually two openings, one low and one high, sized per BTU output to guarantee fresh air intake and exhaust removal.

Always use manufacturer-approved vent kits, seal connections carefully, and avoid blocked or improper installations to prevent carbon monoxide risks and guarantee safe, efficient heater operation.

What Are the Signs of Improper Venting Besides Carbon Monoxide Alarms?

You’ll notice yellow or sooty flame tips, which indicate incomplete combustion from poor venting.

Your heater may produce excessive moisture or condensation on walls and windows.

You might also detect a faint gas odor or hear unusual noises like popping or rumbling.

Additionally, stuffy air, dizziness, headaches, or nausea can signal inadequate ventilation.

Always inspect vents for blockages and never ignore these signs; they compromise safety and require immediate attention.

Can I Install a Vented Propane Heater Myself or Need a Professional?

Installing a vented propane heater isn’t just screwing in a bulb; it’s steering a labyrinth of safety codes and precise airflow calculations.

While you can tackle minor tasks, you really should hire a certified HVAC professional to guarantee proper vent placement, secure sealing, and compliance with regulations.

Mistakes risk carbon monoxide buildup, leaks, or fires.

Professionals bring expertise, tools, and insurance, turning a hazardous puzzle into a safe, efficient heating solution. Don’t gamble with safety.

Your Safety Checklist: Ventilation Is Non-Negotiable

You simply can’t afford to ignore proper ventilation for your propane heater. It’s not just a suggestion; it’s a lifesaver. Without it, dangerous gases like carbon monoxide could silently poison your space, turning comfort into catastrophe.

Whether you choose vented or ventless, always follow strict venting guidelines and inspect regularly. One small oversight could spiral into a full-blown emergency. Stay vigilant, ventilate correctly, and keep your environment safe because your life depends on it.

![How to Clean Syrup off Hardwood Floors: 6 Steps [DIY]](https://anyshelter.com/wp-content/uploads/2023/06/How-to-Clean-Syrup-off-Hardwood-Floors.webp)