Best Adhesives for Formica – Strong, Durable, & Easy to Use

For strong, durable, and easy-to-use adhesives on Formica in 2026, try DAP 00107 for instant bonds on small projects, or DAP’s 32 oz formula for larger, heat-resistant jobs.

BAZIC’s 1 oz glue offers flexible, latex-free bonding ideal for crafts, while 3M Fastbond 30NF suits decorative laminate tasks with low odor and high strength.

Clear-Tite’s waterproof option handles heat well. Exploring these top picks helps you find the perfect match for your specific needs and surfaces.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

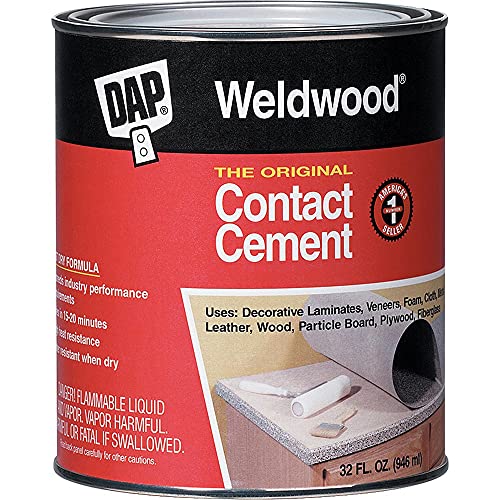

DAP Weldwood Original Contact Cement, Ta...

|

|

|

|

DAP 272 Dap 00 Weldwood The Original Con...

|

|

|

|

BAZIC Products Contact Cement Glue 1 Oz ...

|

|

|

|

3M Fastbond Contact Adhesive 30NF, Neutr...

|

|

|

|

RH Adhesives Clear-Tite Contact Cement, ...

|

|

Key Takeaways

- DAP 00107 Weldwood Original Contact Cement offers instant bonding and water resistance, ideal for small Formica repairs and precise applications.

- DAP Original Contact Cement 32 fl oz provides fast drying, heat resistance, and strong adhesion for large-scale laminate and woodworking projects.

- BAZIC Contact Cement Adhesive Glue ensures a flexible, super-strong bond, suitable for both porous and non-porous surfaces in detailed crafts.

- 3M Fastbond Contact Adhesive 30NF boasts low odor, long open time, and excellent heat tolerance, perfect for decorative laminate and post-forming.

- Clear-Tite Contact Cement sets quickly, is waterproof, and withstands high temperatures, making it excellent for countertops and kitchen cabinetry.

DAP 00107 Weldwood Original Contact Cement,3 oz

- DAP Weldwood Contact Cement forms an instant high strength bond on interior and exterior surfaces...

- Versatile contact cement works for a variety of projects and bonds materials like wood, metal,...

- Contact cement spreads easily, quickly dries tack-free, and offers a 2 hour open time

If you need an adhesive that bonds instantly and holds up against water and chemicals, DAP 00107 Weldwood Original Contact Cement is a smart choice for your Formica projects. This 3-ounce bottle offers a durable, water-resistant bond perfect for applying plastic laminates like Micarta to countertops.

You’ll appreciate how it works on various materials, making your repair or installation smoother. Plus, it resists most chemicals, ensuring long-lasting results. The included handy applicator makes precise application easy, so you won’t waste a drop.

Manufactured in China, this contact cement delivers reliable performance in a compact package.

Best For: DIY enthusiasts and professionals looking for a strong, water-resistant adhesive for bonding plastic laminates and various materials on countertops and other surfaces.

Pros:

- Bonds instantly and permanently on contact, saving time during application.

- Provides a durable, water-resistant bond that resists most chemicals.

- Comes with a handy applicator for precise and efficient use.

Cons:

- Small 3-ounce size may require multiple bottles for larger projects.

DAP Original Contact Cement, 32 Fl Oz, Tan

- Tips for a good project:

- (1) Think ahead

- (2) Permits are important

You’ll appreciate DAP Original Contact Cement for its quick grab and super strength, making it ideal for projects that demand a durable, heat-resistant bond. This neoprene-based, tan liquid adhesive dries in just 15–20 minutes and fully cures around 31 minutes, giving you fast, reliable results.

It’s water-resistant and holds up well under heat, perfect for Formica surfaces, flooring, furniture, and woodworking. The 32-ounce can provides plenty of adhesive for larger jobs, and its medium viscosity ensures easy application.

Trusted by professionals and DIYers alike, DAP Original Contact Cement provides lasting, strong bonds every time.

Best For: Professionals and DIY enthusiasts needing a fast-drying, strong, and heat-resistant adhesive for bonding materials like flooring, furniture, and woodworking projects.

Pros:

- Quick drying time with full cure in about 31 minutes

- Water-resistant and heat-resistant when dry

- Medium viscosity gel formula allows for easy and precise application

Cons:

- Strong odor due to solvent-base formula may require ventilation during use

BAZIC Contact Cement Adhesive Glue 1 Oz

- Strong Multi-Surface Bonding: This contact cement glue delivers powerful adhesion designed for...

- Quick-Drying, Long-Lasting Adhesive Strength: This fast-setting cement glue ensures durable and...

- Versatile Use for Wood, Tile, Plastic, and Rubber: The contact cement adhesive offers multipurpose...

BAZIC Contact Cement Adhesive Glue 1 Oz delivers a flexible, super-strong bond that suits both porous and non-porous surfaces, making it perfect for anyone tackling home improvement or craft projects involving Formica. This latex-free acrylic cement bonds tile, rubber, wood, metal, and plastic with ease.

To use, apply glue to clean, dry surfaces, wait about 10 minutes, then press parts together—clamp heavier items if needed. Its 1 oz size is ideal for smaller projects, while proper storage in a cool, dark place keeps it effective. Clean the tip and recap immediately to prevent curing.

Best For: DIY enthusiasts, crafters, and home improvement users needing a reliable adhesive for bonding various materials like Formica, wood, metal, and plastic.

Pros:

- Flexible, super-strong bond suitable for both porous and non-porous surfaces

- Latex-free, reducing allergy concerns

- Small 1 oz size ideal for precision projects and minimal waste

Cons:

- Heavier materials may need clamping for best results

3M Fastbond Contact Adhesive 30NF, Neutral, 1 Quart Can

- Bonds most foamed plastics, plastic laminate, wood, plywood and canvas to themselves and to each...

- Creates a very high strength, high temperature resistant bond with up to a four hour bonding range

- Adhesive can be applied by spray, brush or roller

Choosing the right adhesive can make or break your Formica project, and 3M Fastbond Contact Adhesive 30NF stands out by offering a strong, long-lasting bond with low odor and VOCs. This neutral, water-based adhesive works great with plastic laminate, wood, canvas, and most foamed plastics, bonding materials to themselves or each other.

You can apply it by spray, brush, or roller, which makes it versatile for decorative laminate work. It’s also high temperature resistant and post-formable, with a bonding range of up to four hours. Plus, it’s non-flammable when wet, reducing fire risks during use.

Best For: Professionals and DIYers who need a strong, versatile, and low-odor adhesive for bonding laminates, wood, foamed plastics, and canvas in decorative and high-temperature applications.

Pros:

- Very high strength bond with long bonding range up to 4 hours

- Low VOCs and non-flammable in wet state, enhancing safety and compliance

- Can be applied by spray, brush, or roller, offering application versatility

Cons:

- Neutral color may not be ideal if adhesive visibility is a concern

Clear-Tite Contact Cement 4 oz Can Waterproof

- High Temperature Adhesive - We've designed the Clear-Tite Contact Cement formula to maintain its...

- Versatile Contact Cement - Use Clear-Tite to adhere a wide range of materials, including metals,...

- Fast Bonding Glue - After applying this adhesive cement to both surfaces, the bond should set in...

If you need a waterproof adhesive that sets quickly and holds up to high temperatures, Clear-Tite Contact Cement is an excellent choice. This 4 oz. can from RH Adhesives bonds laminate flooring, countertops, metals, glass, and more.

You’ll appreciate its fast setting time—just 10 minutes after applying to both surfaces—and its ability to withstand heat up to 250°F. Trusted by commercial designers since 1949, it delivers a strong, long-lasting bond perfect for kitchen cabinets and tabletops.

Made in the USA, Clear-Tite guarantees durability and reliability whenever you’re working with Formica or similar materials.

Best For: Professionals and DIY enthusiasts needing a fast-setting, waterproof adhesive for bonding laminate, wood, metal, glass, and other materials in high-temperature environments.

Pros:

- Sets quickly in about 10 minutes for efficient project completion.

- Waterproof and maintains bond integrity up to 250°F.

- Versatile use on various materials including laminate, wood veneers, metals, and plastics.

Cons:

- Requires application to both surfaces, which may be less convenient than single-surface adhesives.

- Strong bond can make repositioning difficult once surfaces are joined.

Top Adhesives for Formica Comparison

| Product | Size | Key Strength | Heat Resistance | Best For |

|---|---|---|---|---|

| DAP Weldwood Original | 3 oz | Instant permanent bond | High | Laminates to countertops |

| DAP Durable Contact | 32 oz | Exceptional grip | Good (freeze-thaw) | Flooring, woodworking |

| BAZIC Strong Contact | 1 oz | Multi-surface durable | Standard | Tile, rubber, Formica |

| 3M Fastbond 30NF | Varies | High-strength heat bond | High (repositionable) | Laminates, wood |

| RH Clear-Tite | 4 oz | Extreme temp hold | Up to 250°F | Metals, plastics |

Essential Picks for Formica Bonding Success

When you’re picking out adhesive for Formica, it’s important to think about:

Bond Strength Requirements

Although selecting the right adhesive for Formica may seem straightforward, understanding bond strength requirements is crucial to guarantee lasting results. You need to determine if your project calls for strong initial grab to prevent slippage during assembly or ultimate tensile strength to withstand daily wear.

Since peel and shear forces are common on countertops, choose adhesives with high peel strength and shear ratings suited for heavy use. Keep in mind that bond strength hinges on adhesion to both Formica and its substrate, so consider substrate type and porosity.

Also, factor in environmental conditions like moisture and heat, especially near stovetops, by selecting adhesives rated for water resistance and elevated temperatures. Finally, always check manufacturer specs and allow adhesives to fully cure before stressing the bond.

Surface Compatibility

Because Formica bonds best to clean, dry, and grease-free surfaces, you need to prepare substrates like plywood, MDF, or particleboard carefully to guarantee a smooth, flat surface that allows full adhesive contact.

If you’re working with porous materials like raw wood or MDF, choose adhesives with the right viscosity and open time to ensure proper wetting without excessive soak-in.

For non-porous surfaces such as existing laminates, ceramics, or metals, use contact adhesives or primers that create an immediate, strong film rather than penetrating glue.

Also, consider the environment—if the installation faces heat or moisture, pick adhesives that resist water and high temperatures. Finally, removing finishes, lightly sanding glossy surfaces, and degreasing when necessary are essential to avoid contaminants that weaken the bond.

Drying and Curing Time

Choosing the right adhesive for Formica means paying close attention to drying and curing times, as these affect both your workflow and the final bond strength. Contact adhesives usually need 10–30 minutes of tack time before you join surfaces, while water-based types might let you wait for several hours.

Full curing varies widely—many solvent-based cements set in 15–45 minutes but take 24–72 hours to reach max strength. Remember, temperature and humidity impact drying: warm, dry conditions speed it up, while cold or damp environments slow it down.

The thickness of the adhesive layer and how porous your surface is also affect curing times. Always follow the manufacturer’s guidelines for clamping or restricting traffic to avoid stressing the bond before it’s fully cured.

Water and Heat Resistance

You’ll often find that water and heat resistance are critical factors when selecting an adhesive for Formica, especially in kitchens and bathrooms. You want an adhesive labeled “waterproof” or rated under ASTM D6677/D906 to prevent bond failure from spills and steam.

For countertops exposed to heat, pick one with service temperatures up to 200–250°F (93–121°C) to avoid delamination. Also, check if the cured adhesive resists common household cleaners and oils, ensuring the bond stays strong through routine cleaning and food splashes.

It’s smart to review manufacturer data sheets for accelerated aging, water-immersion, or heat-cycling tests to confirm long-term durability. Choosing adhesives with quick contact bonds helps minimize water intrusion and edge lifting on horizontal surfaces.

Application Method

When applying adhesive to Formica, selecting a method that suits your project size and material consistency guarantees a strong, even bond. For large surfaces, use a brush, roller, or spray to guarantee uniform coverage and full contact.

Smaller repairs or trim pieces do better with squeeze tubes or daub methods. Match the adhesive’s viscosity to your chosen application method for smooth, even spreading and pore penetration.

Check the open time—longer open times give you flexibility to reposition large sheets, while shorter ones need faster bonding. Also, consider drying behavior: sprays and rollers typically dry evenly and quickly, unlike some brush-applied solvent adhesives that can puddle.

Finally, make sure your equipment aligns with the adhesive’s safety requirements, especially with solvent-based products needing proper ventilation and explosion-proof sprayers.

Odor and VOC Levels

Although adhesives vary widely in composition, their odor and VOC levels play a crucial role in your indoor Formica projects. Solvent-based contact adhesives often emit strong chemical odors and high VOCs, which can cause headaches, nausea, and respiratory irritation if you don’t ventilate properly.

To avoid this, consider water-based or low-VOC adhesives—they produce much less odor and hazardous emissions, making them safer for indoor use. Always check product labels for “low-VOC” claims or certifications like California’s CARB or SCAQMD standards to gauge emissions.

Even low-odor adhesives off-gas during curing, so follow recommended drying times and keep the area ventilated for 24–72 hours. When working with solvent-based types, wear a NIOSH-rated respirator and make certain local exhaust ventilation to protect yourself effectively.

Flexibility and Durability

Because Formica and its substrates expand and contract with temperature changes, choosing an adhesive with good post-cure flexibility is essential to prevent cracking or bond failure. You want a glue that tolerates flexing and maintains strong adhesion despite these movements.

Look for adhesives proven to keep tensile and shear strength over time, resisting creep under constant stress and temperature shifts. It’s also vital to pick formulations that stay water- and chemical-resistant after curing, especially in kitchens or damp areas, so the bond doesn’t weaken.

High temperature resistance matters too—this keeps the adhesive from softening when exposed to heat from pots or sunlight. If you’re working with thin or bendable surfaces, opt for adhesives with longer open times and elastomeric properties to allow repositioning and handle differential movement smoothly.

Packaging Size Options

Selecting the right packaging size for your adhesive guarantees you have enough product without wasting money or material. For small patches, choose 1–4 oz containers, while large jobs like countertops call for quarts or gallons to avoid running out mid-project.

Always buy 10–20% extra to cover waste from tools, uneven surfaces, or repairs. If your adhesive cures or skins quickly, opt for single-use or resealable containers to maintain freshness.

For ongoing projects or occasional use, pick packaging with applicator-friendly features like brush-in-cap or squeeze tubes to speed up application and reduce contamination. Professionals benefit from bulk sizes due to lower costs but must store adhesives sealed, cool, and ventilated to prevent spoilage and maintain performance over time.

Frequently Asked Questions

Can Adhesives for Formica Be Used on Outdoor Surfaces?

You can use adhesives designed for Formica on outdoor surfaces, but you need to pick ones specifically rated for exterior use. Not all Formica adhesives handle moisture, temperature changes, or UV exposure well.

Look for waterproof, weather-resistant options to guarantee a strong, lasting bond outside. Otherwise, the adhesive might fail quickly. Always check the product label or manufacturer’s guidelines to make certain it suits your outdoor project.

How Long Does It Take for Formica Adhesives to Fully Cure?

It typically takes about 24 to 72 hours for Formica adhesives to fully cure, depending on the specific product and environmental conditions like temperature and humidity.

You’ll want to avoid heavy use or stress on the bonded area during this time to guarantee the strongest hold. Always check the manufacturer’s instructions since curing times can vary, but giving it a full day or more usually guarantees a durable, long-lasting bond.

Are These Adhesives Safe for Use in Kitchens and Food Prep Areas?

You’ll find that most adhesives designed for Formica are as safe as houses when it comes to kitchens and food prep areas. Manufacturers make certain they meet strict safety standards, so you won’t have to worry about harmful chemicals leaching into your food.

Just double-check the product label for food-safe certification, and once cured, these adhesives create a strong bond that won’t compromise your kitchen’s health or hygiene.

Can Formica Adhesives Be Removed Without Damaging the Surface?

Yes, you can remove Formica adhesives without damaging the surface if you’re careful. Start by softening the adhesive with heat from a hairdryer or a heat gun on low. Then, gently scrape it off using a plastic scraper or your fingernail to avoid scratches.

What Is the Shelf Life of Unopened Formica Adhesives?

Unopened Formica adhesives usually have a shelf life of about 12 to 24 months, depending on the brand and storage conditions.

You should keep them in a cool, dry place to maintain their effectiveness. If you store them properly, you can expect the adhesive to remain strong and usable within that time frame.

Always check the manufacturer’s expiration date on the packaging before using to guarantee the best results.

Upgrade Projects with Proven Formica Adhesives

Choosing the right adhesive for Formica can make all the difference in your project’s durability and finish. Did you know that contact cement adhesives boast up to 90% bonding strength within minutes? That means less waiting and more lasting results.

Whether you opt for DAP, 3M, or Clear-Tite, you’re ensuring a strong, reliable hold. So go ahead, pick the adhesive that fits your needs and enjoy a flawless, long-lasting surface every time.

Last update on 2026-02-24 / Affiliate links / Images from Amazon Product Advertising API