What Is Prefinished Hardwood Flooring: Eco-Friendly Flooring

Prefinished hardwood flooring comes ready with stain and a durable finish applied in a factory, so you skip sanding, staining, or sealing on-site. This means faster installation and a flawless, consistent look with options from matte to high gloss.

You’ll enjoy long-lasting durability, easier maintenance, and cleaner indoor air thanks to low-VOC finishes. Plus, you can customize styles and finishes to perfectly suit your space.

Keep exploring, and you’ll uncover all the benefits and design possibilities it offers.

Key Takeaways

- Prefinished hardwood flooring comes factory-finished with stain, sealant, and protective coating, ready for immediate installation without on-site sanding or staining.

- It features durable UV-cured finishes that ensure consistent quality, scratch resistance, and long-lasting wear protection.

- Installation is faster and cleaner, reducing labor time, dust, odors, and VOC emissions compared to site-finished flooring.

- Prefinished planks offer a variety of wood species, plank sizes, finishes, and colors to suit diverse interior styles and preferences.

- The flooring supports healthier indoor air quality and environmental sustainability through low-VOC finishes and responsible wood sourcing.

Definition and Composition of Prefinished Hardwood Flooring

Although you might find unfinished hardwood appealing, prefinished hardwood flooring offers a sleek, ready-to-install solution that saves you time and hassle. It arrives at your home with stain, sealant, and protective finish already applied under precise factory conditions.

This means no on-site sanding, staining, or sealing; just beautiful boards ready to transform your space immediately. Prefinished floors provide high durability due to UV curing during manufacturing, enhancing their longevity.

You’ll appreciate the consistent dimensions and micro-beveled edges that create a polished, modern look while masking subfloor imperfections. These floors are often sealed with polyurethane finishes, which ensure compatibility with gentle yet powerful cleaners specifically formulated for such surfaces.

Prefinished hardwood arrives ready to install, with stain and finish applied flawlessly in the factory, saving you time and effort.

Whether solid wood or engineered, each plank boasts multiple durable finish layers, often enhanced with aluminum oxide for scratch resistance. Plus, the variety of stains and sheens ensures your floor perfectly matches your aesthetic vision, all backed by quality control and finish warranties for lasting beauty and peace of mind.

Advantages of Prefinished Hardwood Flooring Installation

You’re going to love how prefinished hardwood floors come ready to install right out of the box. Seriously, it cuts down on your project time significantly, which means you can enjoy your beautiful new floors much sooner. Additionally, prefinished floors require less on-site finishing, which reduces the need for extensive cleaning such as vacuuming hardwood floors.

Plus, the installation process is pretty neat. It creates minimal dust and has no harsh fumes, so you can breathe easy knowing that your home environment is cleaner and healthier for you and your family.

This really means less disruption in your daily life and helps keep your home feeling fresh and comfortable while the installation is happening. Additionally, prefinished hardwood flooring offers a more durable finish since the protective coating is applied under controlled factory conditions.

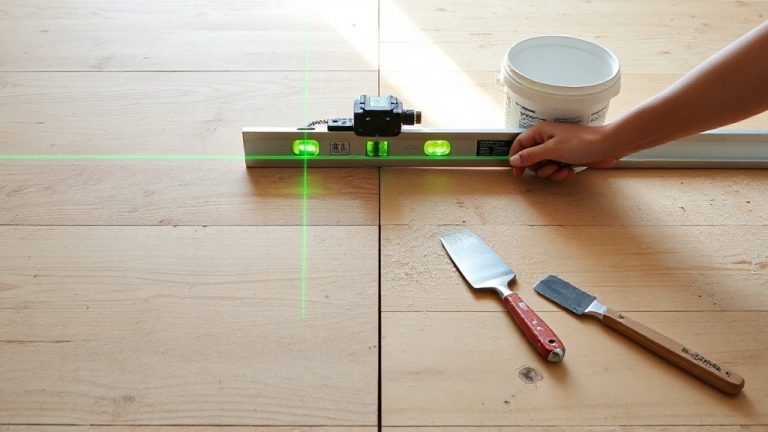

Faster Installation Process

When you choose prefinished hardwood flooring, you cut down your installation time dramatically because the planks arrive factory-sanded, stained, and sealed, ready to be laid without any on-site finishing.

This means installers can typically complete the job within one to two days, sparing you lengthy disruptions. Since there’s no need for sanding, staining, or curing on-site, you can walk on your new floor immediately after installation, accelerating your project’s timeline.

The factory finish offers greater consistency and durability than on-site finishing, ensuring a high-quality surface from the start. Using eco-friendly hardwood cleaners after installation helps maintain that factory finish without damaging the floor’s protective layer.

This efficiency also reduces labor requirements, lowering costs and minimizing human error in finishing. The streamlined process suits tight schedules perfectly, whether you’re renovating a rental or upgrading your home, helping you enjoy your beautifully finished floors faster, with less hassle and greater peace of mind.

Cleaner, Healthier Environment

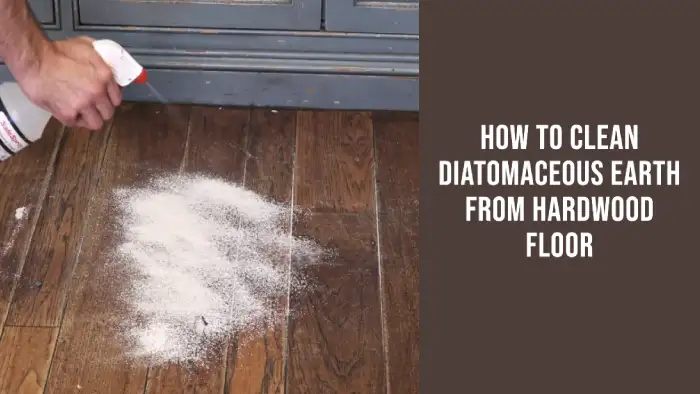

Beyond speeding up installation, prefinished hardwood flooring creates a noticeably cleaner and healthier indoor environment.

Since the sanding, staining, and sealing happen in a factory, you avoid on-site dust, VOC emissions, and chemical odors. This precision minimizes respiratory irritants and keeps your air fresher from day one.

Here’s what you gain:

- Cleaner Air: No on-site finishing means fewer airborne particles and lower VOC exposure, enhancing indoor air quality. Additionally, proper curing time ensures that finishes harden fully, reducing off-gassing indoors.

- Hypoallergenic Surface: Smooth, sealed floors don’t trap allergens or dust, making cleaning effortless and reducing irritants. Wood flooring promotes a healthier indoor environment by reducing allergen accumulation.

- Long-Term Hygiene: Durable finishes resist stains and bacteria, keeping your home fresh and reducing the need for harsh cleaners.

Durability and Quality of Factory-Applied Finishes

Although choosing hardwood flooring is often about aesthetics, the durability and quality of factory-applied finishes play a crucial role in preserving that beauty over time. You’ll benefit from advanced UV-cured coatings with multiple layers, often enriched with aluminum oxide. This makes the surface highly scratch-resistant and moisture-repellent.

These finishes are applied in controlled environments, ensuring consistency and long-lasting protection. Plus, many are low-VOC, keeping your indoor air clean.

Proper moisture content during application and environmental controls are essential to prevent issues like white spots that can affect finish appearance and durability.

| Feature | Benefit | Why It Matters |

|---|---|---|

| UV curing | Hardens finish effectively | Enhances durability |

| Multiple layers | Strong, protective surface | Resists wear and tear |

| Aluminum oxide | Scratch resistance | Maintains flawless look |

| Moisture resistance | Guards against water damage | Extends floor lifespan |

| Low VOC | Improves air quality | Safer indoor environment |

Aesthetic Consistency and Design Options

Because factory-applied finishes guarantee uniform color and sheen, you’ll enjoy a seamlessly cohesive look throughout your hardwood floor. This consistency eliminates blotching or uneven staining, ensuring every plank reflects your chosen design perfectly.

Factory finishes ensure consistent color and sheen, creating a flawless, unified hardwood floor appearance.

Prefinished flooring offers you a variety of wood species, textures, and gloss levels, letting you tailor your space with ease. Keep in mind, though, that customization options are limited to factory palettes. Processed in a controlled factory environment, the quality and finish remain consistently reliable.

Consider these key design advantages:

- Wide range of species and finishes from smooth maple to hand-scraped hickory.

- Multiple sheen options, including matte, satin, or high gloss to match your interior style.

- Trendy colors and plank sizes supporting modern, rustic, or classic aesthetics.

These features let you create a polished, harmonious environment without compromising on style.

Environmental and Health Benefits of Prefinished Flooring

When you choose prefinished hardwood flooring, you’re investing in more than just beauty. You’re embracing a healthier, more sustainable lifestyle.

Prefinished wood locks in a factory-applied finish, minimizing chemical emissions and enhancing indoor air quality. Its smooth surface doesn’t trap dust, allergens, or bacteria, making your home cleaner and safer.

This finish also provides a durable protective layer that resists wear and reduces maintenance needs. Because hardwood forests grow more than twice as fast as they are harvested, this choice supports a renewable resource and sustainable use of natural materials.

Responsibly sourced from FSC-certified forests or reclaimed wood, this flooring supports sustainable forestry and reduces environmental waste.

Hardwood naturally stores carbon, acting as a carbon sink throughout its long life, which can exceed a century with proper care. Its eco-friendly production uses less energy and emits fewer greenhouse gases than synthetic alternatives.

Cost Considerations and Long-Term Value

When you’re thinking about prefinished hardwood flooring, it’s important to balance that initial cost with how long the floor will last and what kind of upkeep it will need.

You see, the factory-applied finish is a real game changer. It not only saves you a lot of time but also provides top-notch protection, which means you’ll spend less on maintenance down the road. This finish also helps prevent issues like surface damage that can occur with improper treatments.

However, keep in mind that the higher material cost of prefinished hardwood can affect your overall budget compared to site-finished options.

So, as you weigh those upfront costs against the long-term benefits, you can make a choice that not only looks great but makes sense for your budget too. It’s all about enhancing your space beautifully while being smart with your money!

Initial Investment Factors

Although prefinished hardwood flooring demands a higher upfront investment than unfinished options, you’ll appreciate the seamless blend of quality materials, expert factory finishes, and efficient installation that together deliver lasting beauty and value. Proper maintenance, including gentle cleaning methods, ensures your floor’s longevity and appearance.

Your initial costs will primarily reflect:

- Material choice – Expect to pay $3-$20 per square foot depending on species and plank size, with factory finishes included.

- Installation complexity – Labor ranges from $3 to $10 per square foot, rising for intricate patterns or subfloor prep.

- Subfloor condition – Repairs or moisture barriers can add $2.20 to $4.75 per square foot but ensure a solid foundation.

Additionally, regional availability and quality impact final pricing, so consulting local suppliers helps obtain accurate estimates. Investing thoughtfully here means a durable, visually stunning floor that adds tangible long-term value and minimizes future expenses.

Durability and Maintenance Costs

Investing in prefinished hardwood flooring means you’re not just paying for upfront quality. You’re also securing a surface built to endure daily life with minimal upkeep. Using the right cleaning products, such as those with a pH-balanced, water-based formula, helps maintain the finish without damaging the wood.

The factory-applied aluminum oxide finish offers exceptional scratch resistance and color stability, drastically reducing maintenance needs. This consistent finish layer provides better protection against wear and tear, enhancing the floor’s lifespan. Choosing harder species like hickory or hard maple boosts durability, minimizing dents and repairs over time.

While these floors demand only routine cleaning and occasional recoating, their finishes resist wear far better than site-finished alternatives. Though recoating aluminum oxide finishes isn’t simple, their longevity and minimal maintenance translate to significant cost savings.

Frequently Asked Questions

Can Prefinished Hardwood Flooring Be Refinished if Damaged?

Yes, you can refinish prefinished hardwood flooring if it’s damaged, but it’s a bit trickier than with traditional floors. You’ll want to contemplate the thickness and type of wood since too thin boards mightn’t handle sanding well.

Refinishing restores beauty, lets you change colors, and extends lifespan, but be mindful of visible scratches and maintaining the floor’s unique texture. Proper refinishing keeps your space looking flawless and fresh.

How Does Prefinished Flooring Perform in Humid Climates?

You’ll find prefinished flooring performs quite well in humid climates, especially when it has moisture-resistant finishes that protect surfaces from absorption.

Its factory-applied coating creates a sleek barrier, reducing warping and swelling. Still, you’ll want to maintain stable indoor humidity levels to keep your floors looking flawless.

With proper acclimation and care, prefinished flooring combines beauty and durability, letting you enjoy rich wood tones without worrying about moisture damage.

What Types of Subfloors Are Compatible With Prefinished Hardwood?

You’ll want to choose plywood or oriented strand board (OSB) subfloors at least 5/8-inch thick for a sturdy, smooth base.

If your subfloor is concrete, make sure it’s clean, flat, and dry. Adding a plywood underlayment helps.

Avoid particleboard alone unless you overlay it with quality plywood.

For solid wood boards, add plywood for stability.

Proper flatness, fastening, and moisture control will make your prefinished hardwood flooring look flawless and last beautifully.

Are There Specific Maintenance Tips Unique to Prefinished Hardwood?

You can’t just toss water and mop around like it’s a swamp! Prefinished hardwood demands delicate care: sweep daily with microfiber mops to dodge scratches and vacuum weekly without beater bars.

Spill? Blot immediately; no lounging allowed. Use only hardwood-specific cleaners, never wax or vinegar.

Keep furniture gentle with protectors and trim pet nails. Treat your floor like fine art, and it’ll keep glowing beautifully for years.

Can Prefinished Hardwood Flooring Be Installed Over Radiant Heating Systems?

Yes, you can install prefinished hardwood flooring over radiant heating systems, but you’ll want engineered hardwood for the best results.

Its layered construction handles heat better, reducing risks of warping or gaps. Keep floor temperatures below 80°F and allow the wood to acclimate properly before installation.

With careful attention to subfloor prep and temperature control, your radiant-heated floors will stay stunning and durable, blending comfort with elegant design effortlessly.

More Than Just Wood – It’s an Investment in Comfort and Style

Choosing prefinished hardwood flooring means embracing both convenience and quality. You get a stunning, consistent look without the mess and wait of on-site finishing. While traditional floors offer customization, prefinished options deliver durability and eco-friendly peace of mind straight from the factory.

You’re investing not just in wood, but in time saved, health preserved, and style perfected. It’s the smart, beautiful choice that balances ease with lasting elegance for your home.