What Is Hardwood Veneer: Aesthetic Meet Structural Integrity

You work with hardwood veneer when you use thin, natural wood slices, usually under 1/40 inch thick, carefully cut by methods like rotary peeling or quarter slicing. These veneers retain authentic grain and color and get laminated onto stable substrates to prevent warping and allow flexibility.

Engineered veneers enhance durability and dimensional stability for varied applications. If you want a precise understanding of manufacturing, cutting techniques, benefits, and sustainability, there’s much more to explore.

Key Takeaways

- Hardwood veneer consists of thin slices of natural hardwood, typically less than 1/40 inch thick, showcasing authentic wood grain and texture.

- It is produced by slicing or peeling logs through methods like rotary cutting, plain sawing, or quarter sawing.

- Veneers are laminated onto substrates such as plywood or MDF to enhance stability and reduce warping.

- Hardwood veneer offers a flexible, lightweight alternative to solid wood while maintaining natural wood aesthetics.

- It is widely used in furniture, cabinetry, architectural paneling, and curved surface applications for decorative finishes.

Definition and Key Features of Hardwood Veneer

What exactly defines hardwood veneer and sets it apart from solid wood? Hardwood veneer consists of extremely thin slices of natural hardwood, typically under 1/40 inch thick, cut using methods such as plain sawing, quarter sawing, or rotary cutting.

These thin sheets retain the authentic color, grain, and texture of the original hardwood species. Unlike solid wood, veneer is laminated onto stable substrates like plywood or MDF, enhancing dimensional stability and reducing warping risks.

This approach maximizes the use of valuable hardwood by expanding surface area from fewer logs, making it more economical and sustainable. The veneer’s thinness also allows flexibility for curved surfaces while preserving natural wood aesthetics.

Its consistent grain patterns, depending on cutting techniques, enable precise matching for large panels and specific design effects. To maintain the beauty and longevity of hardwood surfaces, regular cleaning methods such as gentle sweeping or vacuuming with soft attachments are recommended.

Step-by-Step Hardwood Veneer Manufacturing Process

Before veneer sheets can be produced, logs undergo meticulous preparation involving sorting by species, controlled soaking or humidity conditioning, and debarking to preserve surface integrity. Proper debarking improves overall veneer quality and grain matching, which is crucial for the final product’s aesthetic appeal.

Next, logs are steamed or soaked at 80–100°C for 18–72 hours to soften fibers, then cut into peeler blocks labeled for tracking.

You’ll mount these blocks on lathes or slicing machines to peel or slice veneer sheets, typically 0.5–3 mm thick. Different cutting methods such as rotary slicing, flat slicing, quarter slicing, and rift slicing influence the grain appearance and uniformity of the veneer sheets.

Immediately after slicing, dry the sheets using hot air or rotary dryers, controlling temperature to reduce moisture to 6–8% and prevent warping. Proper moisture control avoids cracking and deformation, ensuring the veneer remains flat and structurally sound over time.

Each sheet undergoes rigorous inspection for defects, followed by grading based on appearance and usability.

Finally, clips trim sheets to standard sizes before bundling and packaging, ensuring protection and traceability throughout shipment. The use of backing materials like phenolic can be applied to enhance veneer stability for demanding projects.

Different Cutting Methods for Hardwood Veneer

When selecting hardwood veneer, you’ll encounter several cutting methods that directly affect the grain pattern, yield, and application suitability. Rotary cutting peels veneer continuously from a rotating log, producing wide, bold, irregular grains ideal for plywood but less suited for fine furniture.

This method involves mounting the log on a lathe and turning it against a stationary knife to peel off the veneer like unrolling paper, resulting in a continuous sheet of veneer. Proper moisture control is essential to prevent damage when using these veneers in construction.

Plain slicing cuts parallel to growth rings, revealing a cathedral grain pattern widely favored for cabinetry and doors due to its balanced aesthetics and cost. Ensuring the veneer is kept dry and protected with appropriate coverings can extend its durability and appearance.

Quarter slicing, cutting perpendicular to growth rings, yields straight, refined grains with “flake” figures, preferred for high-end furniture despite higher cost and lower yield. Using an insulation blanket around storage areas can help maintain stable conditions for these premium veneers.

Rift-cutting, a variant of quarter slicing with off-radius cuts, produces tight, uniform linear grains with minimal fleck, commonly used in sleek, modern designs but at increased material waste. Proper sealing and protection from moisture ingress are recommended to preserve the quality of rift-cut veneers.

Comparing Natural and Engineered Hardwood Veneers

When it comes to hardwood veneers, you’ll really notice that natural hardwood veneer brings a unique charm. It showcases authentic grain patterns and those little imperfections that come straight from the log. This gives it an unmatched visual depth and character that many people love. Natural hardwood also provides a timeless, elegant look that enhances interior design and complements existing decor.

On the flip side, engineered veneer has its own set of advantages. Thanks to its layered construction and controlled manufacturing process, it offers enhanced dimensional stability and a more uniform appearance. It is also generally more affordable, making it a great option for budget-conscious projects cost-effective choice.

So, when you’re trying to decide which veneer type is best for you, it’s important to consider these differences. Think about what matters most: the look you want, how it performs, and what your specific application needs are. That way, you can pick the perfect veneer for your project!

Natural Veneer Characteristics

Although engineered hardwood veneers offer uniformity and controlled aesthetics, natural wood veneers provide unmatched texture and visual complexity due to their origin from real trees. You’ll notice unique grain patterns shaped by growth rings, environment, and cutting methods such as flat-sawn or quarter-sawn, producing varied textures and color variations.

Natural blemishes like knots and mineral streaks add depth and character, impossible to replicate in engineered products. This organic variability offers a one-of-a-kind appearance, especially in premium species like cherry or walnut influenced by geographic factors.

While natural veneers demand careful handling due to susceptibility to surface defects and color fading, their authentic aesthetic and tactile connection to nature make them highly valued in luxury applications. Proper maintenance, such as avoiding excessive moisture, is crucial to preserve their integrity over time.

Sustainable sourcing and minimal processing further enhance their environmental and health advantages.

Engineered Veneer Advantages

Because engineered hardwood veneers incorporate a multi-layer core beneath the thin hardwood surface, they offer superior dimensional stability compared to natural solid wood. This layered construction resists expansion, contraction, warping, and cupping caused by humidity and temperature fluctuations.

This enables installation in moisture-prone areas like basements and kitchens. The veneer thickness directly impacts durability; thicker veneers allow multiple refinishing cycles and better wear resistance, preserving the wood’s natural grain.

Additionally, the core layer often consists of plywood, HDF, or hardwood veneers, which contributes to the flooring’s enhanced dimensional stability. Engineered veneers also provide installation flexibility, compatible with floating, glue-down, or nail-down methods.

They accommodate subfloors unsuitable for solid wood, such as concrete or radiant heating, and perform well with radiant heating systems. Pre-finished wear layers enhance scratch and stain resistance, reducing maintenance compared to unfinished solid wood.

These advantages combine structural resilience, aesthetic variety, and practical adaptability that natural veneers alone can’t match.

Essential Equipment Used in Hardwood Veneer Production

When it comes to starting hardwood veneer production, the first thing you’ll need to do is select the right machinery. It all begins with the rotary lathe. This machine is pretty impressive; it peels logs into continuous sheets while ensuring they’ve a consistent thickness and beautiful, broad grain patterns. Proper maintenance and cleaning of the lathe are essential to prevent contamination and damage during operation.

Once you’ve got your sheets, you might want to look into slicing machines. These come with options for flat or quarter slicing, and each type offers its own unique grain orientations and dimensions. This is really important, especially when you’re considering both aesthetic appeal and structural integrity for your projects.

To further refine the veneer sheets, surface finishing equipment such as sanding machines is used to produce smoother, more delicate surfaces by removing burrs and uneven parts, enhancing the overall appearance and quality.

And don’t forget about half-round lathes! They provide a hybrid peeling method that combines the best of both rotary and slicing techniques. This can be particularly useful when you need specialized veneer profiles.

Rotary Lathe Functionality

When you operate a rotary lathe, the log spins rapidly against a fixed blade, peeling off continuous sheets of veneer with remarkable uniformity. The log mounts on a spindle rotating at high speed, allowing you to control veneer thickness precisely, typically between 0.3 mm and 3.0 mm, via hydraulically adjusted knife carriages.

Pressure bars stabilize the veneer against the blade, ensuring consistent cutting quality. Computerized controls let you fine-tune knife pitch and peel rate by increments as small as 0.001 inches, adapting to species, temperature, and log diameter.

After peeling, a core drive system ejects the log core efficiently, minimizing downtime. Heavy-duty frames support large hardwood logs up to 2600 mm long. The machine structure is built using good, thick materials to ensure durability and reliable operation.

This precise, automated setup optimizes veneer quality, recovery, and production throughput in hardwood veneer manufacturing. Proper maintenance and cleaning routines of equipment are essential to preserve performance and prevent damage during production.

Slicing Machine Types

Rotary lathes set the foundation by peeling logs into continuous veneer sheets. Slicing machines take over to cut these sheets with high precision and speed, ensuring a smooth surface ready for finishing.

You’ll find several slicing machine types tailored for veneer production: spindleless and spindle veneer peeling machines accommodate varying log diameters up to 1300mm. Rotary cut and horizontal veneer peeling slicers utilize hydraulic pressure technology for efficient slicing.

These machines employ advanced five-axis servo control systems to maintain a close shave for consistent thickness. The carriage and blade systems are powered by 15-hp motors, ensuring smooth feed rates. The typical operation speed reaches up to 90 strokes/min, optimizing production efficiency.

Pressure bar adjustments and dual 1.3-hp servomotors fine-tune blade clearance, eliminating inconsistencies. Equipped with electronic controls and easy knife replacement systems, slicing machines handle logs up to 18 feet long and 10,000 pounds. Proper maintenance and routine inspection of blades are crucial to preserve cutting quality and prevent floor or surface damage.

Half-Round Lathe Use

Although less commonly discussed than rotary lathes, half-round lathes play a crucial role in hardwood veneer production by enabling the precise cutting of logs positioned off-center on the lathe.

You mount the log between centers, deliberately off-center, allowing the blade to contact only the protruding portion as it rotates. This setup produces semi-circular veneer slices with unique grain patterns and reduced internal stresses. This technique helps preserve the natural wood grain and enhances the aesthetic appeal of the veneer.

You must adjust the tool rest height to log center and continuously fine-tune tool position as the log diameter decreases. This approach requires skilled management of the cutting tool to maintain proper cutting technique.

Using gouges shaped for half-round cutting, you achieve smooth, clean veneer surfaces while minimizing waste. This method excels at peeling dense hardwoods, maintaining structural integrity and ideal appearance, making the half-round lathe indispensable for specialized veneer profiles.

Popular Hardwood Species Used for Veneers

Oak, with its distinct grain and two varieties, Red Oak’s warm tones and White Oak’s neutral hues, is durable and stain-friendly, making it widely used. Walnut offers rich dark browns and subtle grain patterns, prized for luxury furniture and stability.

Maple features light creamy colors and fine grain, valued for hardness and decorative variants like curly maple. It is also grown domestically, reducing environmental impact and ensuring sustainable sourcing.

Cherry veneer’s warm reddish-brown tones deepen with age, providing smooth grain and elegance for various furniture styles. Mahogany displays deep reddish to golden tones with straight or interlocking grain, noted for luxury and durability in high-end applications.

Each species balances aesthetics, structural integrity, and availability, making them preferred veneer materials in woodworking.

Common Applications of Hardwood Veneer in Design

You can really elevate your furniture by applying hardwood veneer. It’s a fantastic way to achieve those intricate grain patterns and luxurious finishes, all without breaking the bank. Just think about using it on substrates like MDF or plywood—it’s a game changer!

Hardwood veneer is especially suitable for curved projects due to its flexibility, allowing designers to create unique shapes with ease. Choosing the right veneer color can also complement your overall design scheme by matching warm natural tones popular in interior trends.

And it doesn’t stop there. Veneers are also great for architectural surface treatments. They provide a uniform and lightweight solution for wall paneling and ceilings. This means you can add depth and texture to a space without the bulkiness of solid wood.

Additionally, selecting veneers with suitable finishes can enhance durability and ease of maintenance in busy environments. It’s pretty amazing how these applications can expand your design possibilities while still keeping things structurally efficient and visually cohesive.

Furniture Enhancements

How does hardwood veneer elevate furniture design beyond mere surface covering? It delivers intricate grain patterns like book-matching, creating striking visual effects while using less wood, making rare or exotic appearances accessible.

You get consistent grain matching, enhancing design cohesion across pieces. Veneer’s thin, lightweight nature reduces furniture weight, enabling complex shapes and large elements without added bulk or cost. This is possible because veneers are thin slices of real wood bonded to substrates.

This flexibility supports built-in units and ergonomic details, maintaining durability comparable to solid wood. You also benefit from cost-effective luxury—achieving premium hardwood aesthetics affordably while promoting sustainability by minimizing wood waste.

Additionally, treated veneers resist humidity and wear, making them ideal for kitchens and bathrooms. Overall, hardwood veneer enhances furniture with functional durability, design versatility, and refined aesthetics, balancing performance with sophisticated style.

Architectural Surface Treatments

You’ll find it transforming large vertical surfaces through wall paneling and acoustic treatments, where seamless grain matching creates a refined aesthetic while improving sound quality. Different cutting techniques such as rotary cutting and flat slicing produce distinct visual effects that enhance these applications.

In cabinetry and millwork, veneers offer consistent wood finishes, especially quarter-sliced or book-matched patterns, balancing visual appeal with stability and cost-effectiveness. When dealing with curved or radius surfaces, thin, flexible veneers conform precisely to complex shapes, maintaining natural grain appearance without added weight.

For custom architectural accents and feature walls, veneers provide dramatic, large-scale patterns that enhance focal points and work harmoniously with lighting.

Additionally, using veneers supports sustainability by maximizing wood yield, reducing waste, and contributing to green building standards, making them a technically superior choice for diverse architectural applications.

Advantages of Using Hardwood Veneer Over Solid Wood

Although solid wood has long been favored for furniture, hardwood veneer offers distinct advantages that enhance cost-effectiveness, stability, and design flexibility. Veneer maximizes raw material use by slicing thin layers from a single log, reducing costs and waste while enabling affordable access to exotic woods.

Thin layers from one log optimize material use, cut costs, and make exotic woods accessible.

Its bonding to stable substrates like MDF minimizes warping and dimensional changes caused by humidity, ensuring better long-term structural performance and reduced maintenance. This construction technique allows veneer to maintain a consistent appearance that solid wood cannot always guarantee.

You’ll also benefit from veneer’s design versatility, as it allows precise grain matching and intricate patterning on large surfaces unattainable with solid wood.

Additionally, veneer furniture is markedly lighter, easing transport and handling without compromising strength. These combined factors make hardwood veneer a technically superior and economically efficient alternative to solid wood for many applications.

Environmental Impact and Sustainability of Hardwood Veneer

Because energy consumption dominates the environmental footprint of hardwood veneer production, understanding its sources is crucial for evaluating sustainability. Thermal and electrical energy each account for roughly one-third of emissions and drive the majority of greenhouse gases.

Fossil fuel use, particularly natural gas, contributes considerably. Transportation, typically spanning 500 km in Europe, impacts eutrophication and acidification but represents only about 5% of the total environmental burden.

Hardwood veneer stores biogenic carbon, offering notable carbon sequestration benefits that offset emissions throughout its lifecycle. Sourced primarily from sustainably managed forests, veneer is renewable, recyclable, and biodegradable.

Life cycle assessment data demonstrate that U.S. hardwoods, including veneer, generally have a low environmental impact from extraction through disposal. Life cycle assessments emphasize the importance of biomass-based energy inputs and efficient manufacturing to reduce global warming potential.

You should also consider industry certifications and environmental product declarations that ensure transparency and adherence to sustainability standards.

Tips for Selecting Quality Hardwood Veneer

When selecting quality hardwood veneer, you need to carefully evaluate several critical factors that directly influence both appearance and performance.

First, prioritize veneer grade: choose AA for flawless, uniform color and grain on visible surfaces, or opt for lower grades if cost is a concern. Understanding veneer grades ensures selection of the best quality for specific applications, helping you balance appearance with budget by selecting from veneer face grades.

Consider wood species based on durability, hardness, and aesthetic goals. Oak offers robustness, walnut provides rich coloration, while exotic woods add unique grain but at higher cost. Match veneer cut type—rotary, quarter, or rift—to desired grain pattern and texture, ensuring consistent thickness for durability.

Conduct thorough inspection for defects like knots, splits, or stains, using expert judgment to detect hidden flaws. Finally, verify backing compatibility and environmental suitability, balancing cost against finish potential and long-term stability for your project’s demands.

Frequently Asked Questions

How Should Hardwood Veneer Be Maintained and Cleaned Over Time?

You should dust hardwood veneer weekly with a soft microfiber cloth, wiping gently along the grain using a damp cloth lightly moistened with diluted mild soap. Dry immediately to prevent moisture damage. Treat stains promptly by blotting, avoiding harsh scrubbing.

Use pH-balanced, non-abrasive cleaners and limit wax use. Protect surfaces with coasters and felt pads, control humidity between 40-60%, and avoid direct sunlight to preserve veneer integrity and appearance over time.

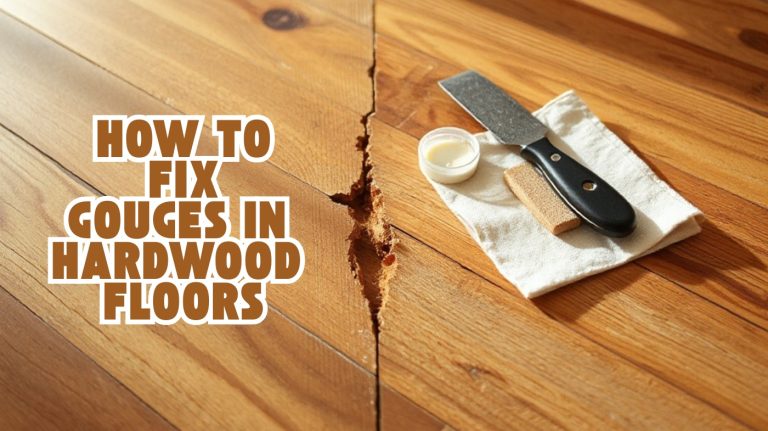

Can Hardwood Veneer Be Repaired if Scratched or Damaged?

Yes, you can repair scratched or damaged hardwood veneer. Start by filling scratches or cracks with a color-matched wood filler or putty. Then sand lightly and stain to blend.

For peeling veneer, re-glue it with wood glue and clamp firmly until dry. Larger damage requires removing the damaged section, fitting a matching replacement, gluing, sanding, and refinishing carefully to guarantee seamless restoration and extend your veneer’s lifespan.

What Is the Average Lifespan of Hardwood Veneer Furniture?

Think of hardwood veneer furniture as a finely crafted ship steering through years of changing seas. With proper care, its average lifespan ranges from several decades up to 50 years or more. This durability hinges on quality core materials, veneer thickness, and maintenance.

You’ll want to control humidity, avoid sunlight, and prevent physical damage. While veneer resists warping better than solid wood, refinishing options are limited. Timely repairs are key to extending its voyaging years.

Are There Any Health Concerns When Working With Hardwood Veneer?

Yes, you face significant health risks working with hardwood veneer. Inhaling dust can cause lung damage, asthma, or cancer, especially from treated veneers containing formaldehyde or resins.

Dust also irritates your skin and eyes, possibly causing dermatitis or conjunctivitis. Chemical exposure through skin or lungs may trigger systemic symptoms or allergic reactions. To safeguard yourself, use respirators, gloves, goggles, guarantee proper ventilation, and follow strict safety protocols consistently.

How Does Humidity Affect Hardwood Veneer Installation and Performance?

Think of hardwood veneer as a sponge dancing with the air. When humidity rises, it swells; when it falls, it shrinks. If you don’t acclimate the veneer for 3-4 days and control the environment’s humidity between 30-50%, you risk warping, cracking, or gaps.

Using a hygrometer helps you monitor conditions precisely, ensuring stable installation and lasting performance. Neglecting these steps invites failure, making your veneer vulnerable to nature’s invisible tug-of-war.

Choose the Right Cutting Method for the Look You Want

Choosing hardwood veneer is like selecting the perfect skin for your project. It offers the rich beauty of solid wood with enhanced versatility and sustainability. By understanding its manufacturing, cutting methods, and applications, you can confidently optimize your design’s aesthetic and structural integrity.

Keep in mind the environmental benefits and quality indicators to guarantee your veneer not only looks exceptional but also performs reliably over time. This makes it a smart, technically sound choice for your work.